Welcome to a Leader in Industrial Solutions Since 1974

Our Customers: A Partner for the Future

Welcome to a Leader in Industrial Solutions Since 1974

Our Customers: A Partner for the Future

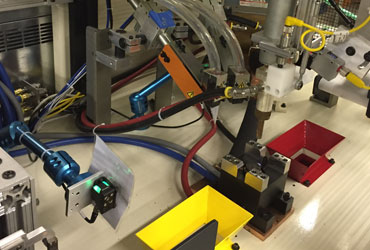

Our experienced team of project managers, mechanical engineers, controls engineers, machinists and assemblers design and produce robust custom solutions that offer long-term reliability. Our modern manufacturing facility is equipped with cutting-edge production machinery and processes, from advanced sensor and robotics to work cells.

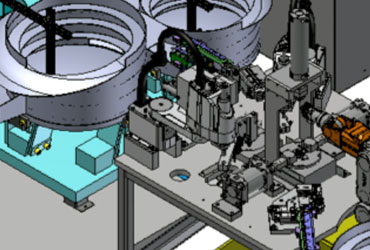

Our engineers can work with current or create new designs to fit customer requirements using 3D modeling software, .

Read more

Onsite or new deployments, utilizing all major controls platforms for PLC/HMI/Robotics, our team can provide the solution.

Read more

The Glaze Tool and Engineering highly experienced group of machine builders and engineers can provide the automated solution required.

Read more

With an average of 25 years’ experience, Glaze Tool and Engineering highly skilled machinists and tool makers can meet your needs.

Read more

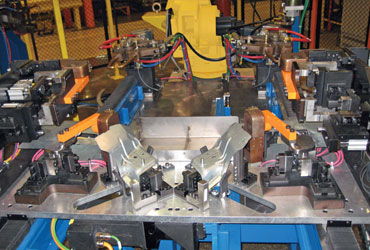

Glaze Tool and Engineering has designed and built dies, fixtures and special machinery for a wide variety of industries all under one roof.

Read more

We can provide standalone controls design and panel build utilizing customer documentation or design to requirements.

Read more

At Glaze we can produce every type of welding and fabrication you can possibly imagine...no matter what your specifications.

Read more

Our staff is available to come to your facility to assist with solution development that can only be done at a customer’s facility.

Read more

We have a staff of qualified service technicians and electrical engineers who can get your equipment back up and running.

Read moreYes, if you need a part for an existing piece of equipment and you don't have drawings or documentation. Our engineering department can reverse-engineer a single part or multiple parts of your machine. When our work is complete, you’ll have the needed drawing to accompany your part for any future needs.

We’re available for extended hours to provide convenient emergency and same-day service. The engineering department is always on hand to lend support and offer solutions or suggestions.

We work with you through the entire system development process, from initial systems concept to final integration. All along the way, our engineers can help you make informed decisions about your manufacturing requirements and resources.

Large projects or small. Whether your project needs a full design and build, an improvement of a current design, or a duplicate of a current system, Glaze is your best value supplier.

A case study from Glaze highlighting a significant improvements in production output and workplace safety.

We’re excited to announce a significant addition to our company’s toolkit: the Bambu Labs X1C 3D printer!

On August 9th, Glaze Tool and Engineering celebrated a major milestone—our 50th anniversary—with a memorable open house event.

We reflect on a journey that spans three generations, a legacy of hard work, growth, and commitment to our customers.

The prestigious Made in Indiana program, in collaboration with Purdue Manufacturing Extension Partnership (MEP).

The Conexus Manufacturing Readiness Grant supports manufacturers in making innovative capital investments in smart manufacturing.

Glaze Tool and Engineering is bursting at the seams. In light of this, we've decided to add on to our building and increase our capacity.

Our new 3D Laser Scanner digitally scans complex assemblies into our native CAD software for reverse engineering.

Our Haas high-performance Super-Speed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes.

New Milltronics ML 18/60 19" Dia. x 63" travel and a new Milltronics ML 26/80 27" Dia. x 84" travel thru bore.

Glaze Tool and Engineering can now laser mark parts with their new Laser Marking System purchased in 2019.